The present value of both types of objects can only be read. The heatnet™ bridge is an oem product called a protocessor manufactured by fieldserver.

Learn more about bacnet driver

Heatnet bacnet registers. The bacnet driver allows your gateway to make two different configurations: Kn boiler manual kn vent/air manual th is manual is intended only for use by a qualifi ed heating installer/technician. On the master boiler's lcd display, go to settings and then menu page 3 and press 'heatnet online'.

To bacnet binary inputs (bi) and modbus input registers should be assigned to bacnet analog inputs (ai). Read and follow this manual, all supplements and related instructional information provided with the boiler. Designed for precise system control, heat net provides repeatability and feedback thru digital communication.

The network is usually designed by a controls contractor and thus, we have no way of knowing the device addressing scheme being used. Modbus coils as well as bacnet binary outputs could be read or written. Learn how to configure both in this video.

11 rows the egauge does not have a fixed bacnet register map. Then check the 'commissioned' checkbox to commission the system. Local devices, which register the gateway as a bacnet capable entity, and remote devices which represent other bacnet/ip capable systems that you want ignition to communicate with.

Added the ability for a boiler to take itself offline from heatnet when the return water temperature is below a threshold. Our technical support team can be contacted: Modbus, lonworks and bacnet bms integration.

There should be a column for read/write access. Local setpoint boiler is watching the. Controls heatnet communication protocols v1.01;

These ports need to be configured for bacnet/ip in the configuration file. Th e control method used by the heatnet control is based on digital communications, which eliminates the need for analog control signals. Modbus coils should be assigned to bacnet binary outputs (bo).

Take a look at the mt3's bacnet object list documentation. Changing bacnet settings on a heatnet bridge v1.10. To allow heatnet online to properly decode a fault.

Controls fiii lonworks network variables; Every control network requires that each device have a unique address (ip, mac, bacnet node id, etc.). The control method used by the heatnet control is based on digital communications, which eliminates the need for analog control signals.

This feature would primarily be used to keep non Analog signal inputs are supported, but a higher level of control precision, repeatability and feedback is gained Controls finding a lost heat net bridge;

Controls changing ip settings on a heatnet bridge Every control network requires that each device have a unique address (ip, mac, bacnet node id, etc.). The native modbus registers to the appropriate protocol (bacnet, lonworks, etc.).

Increased the maximum add boiler delay time from 15 minutes to 1 hour due to requests. Dhw setpoint the dhw sensor is controlling the setpoint for dhw heating. For modbus devices it will be necessary to consult the user’s manual to understand the meaning of the modbus registers.

Controls fiii bacnet objects (legacy) controls fiii bacnet objects v2.40; There is however, a way to create bacnet objects from modbus registers using the anybus bacnet to modbus gateway. The support section of our web site is geared towards current owners of our products.

Also, note the 'unit id' field on this screen, you will need this in the next step. Category ii and iv venting. Configure the controller according to manufacturer’s instructions.

Read and follow this manual,. You want to find an object that has a c in that column, indicating that it is commandable (read/write) and supports a priority array.

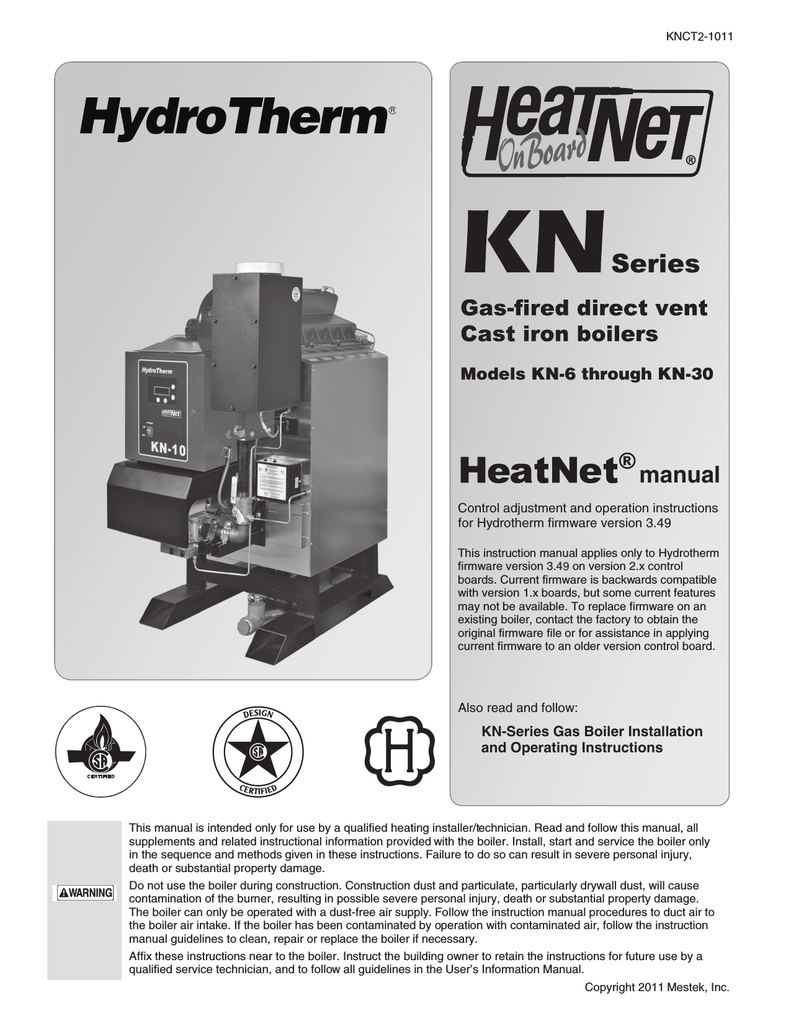

Hydrotherm Heatnet Kn-10 Manual | Manualzz

-

Active standard astm e935 | developed by subcommittee: E935 standard test methods for performance of permanent metal railing systems and ra...

-

Commercial boilers www read all instructions in this ma. Click below for a larger image. Axeman Anderson Wiring | Stoker Coal Boilers Usi...

-

Step by step demonstration of how to remove permanent marker from clothing and clothing labels. Did your child come home from school with Sh...

i wish it was

I Wish It Was 1989 Lyric video YouTube . Web I Wish It Was 1989 Lyric video Scouting For Girls 69K subscribers Subscribe 197 7.9K vie...

ads